Sun is the ultimate source of all energy, this is something taught since primary school. This basic knowledge is revisited each time a façade engineer decides to specify the optical and thermal properties of glass for a project. Glass has many benefits that make them a popular choice among architects for building façades. They are aesthetically pleasing in a cityscape and create an inviting entrance for a building. Glazed walls create the impression of open and airy space and improve the overall mood created in a building. Glass also allows a lot of natural light and heat to enter a building thus allowing to effectively reducing heating and artificial lighting cost.

While glass offers all the above benefits, these same properties of glass can also create negative atmosphere in a building. Windows and glazing can be understood to be the least insulating element of a building assembly. The building façades design has immense influence on daylighting, solar heat gain and natural ventilation, which are closely related to the lighting and air conditioning energy consumption for a building. Therefore, windows must be carefully designed to control the solar gains to suit different climatic regions and orientations.

Solar energy incident on any glazed surface comprises light and heat. 55% of solar energy incident on Earth comprises heat and slightly over 40% is visible light. This simply means separating the light and heat out of the solar spectrum is impossible. Normal clear glass is almost completely transparent to high frequency solar radiation (visible and infrared) but is a barrier to low frequency. As solar radiation strikes the façade, the solar heat energy passing through the glazing tends to warm up the internal surfaces by absorption, and these internal surfaces become heat radiators. However, the heat reemitted is low-frequency radiation of which the glass is a barrier. This is called the greenhouse effect.

U-Value: One of the most used terminologies, is the amount of heat passing through the glazing, per unit of surface area, for a difference in temperature of 1°K on each side of the glass. This property is related mostly to the conductivity of the material.

Windows with low U-value must be considered for energy efficiency and thermal comfort. It is important to note that the whole system U-value will always be considerably higher than glass center u-values. Regulatory codes and bodies specify whole system u-values and to achieve these values along with framing area, it is important for engineers to specify glass with a much lower center u-value. As seen from the image, the frame area behaves as zones of high heat transfer.

Air is a good insulator, and therefore the u-value of an insulated glazing unit(low-e glass) is much better than that of single glazing. The image shows a treated DGU glass, the total transmission has been reduced to 21% compared to the 87% of clear 3mm glass.

Solar Factor (SF) or G-value is the amount of solar energy which passes through a glazed area of a building when compared with the total incident energy upon the glazing. This is also called SHGC (solar heat gain coefficient). This gives a measure of the capacity of the glass to allow/ block heat energy from passing through. Typically, windows with low SHGC values of 0.25 are desirable in buildings with high air conditioning loads while windows with high SHGC values are desirable in buildings where passive solar heating is needed.

Shading coefficient (SC): a term commonly heard in the industry is the ratio of the solar factor of the evaluated glazing unit to the solar factor of a 3 mm single glazing. SC= SF/0.87. This simply means that a 3mm single glazing allows 87% of the incident solar energy to pass through. Local regulations and international codes limit the values of SC for the purpose and location of a building. Skylights typically must be designed to have low SC values of 0.25 as it contributes to major heat gain within a space. Offices, residences schools, and hospitals must also be designed with low SC values of 0.3 or lower for improved comfort and energy efficiency within the space. Retail spaces will need to be designed with higher SC values since light transmission is a major aesthetic factor governing the selection of glass for use on these projects.

The main light/ visual parameters of glazing are:

Light Transmittance (LT ): It is the fraction of the visible spectrum of sunlight, which is transmitted through a window door or skylight glazing. LT is expressed as a number between 0 and 100%. Glass with higher LT transits more natural light into a space. The governing values for light transmission will be provided by local regulations and sustainability considerations for the location and usage of the project. Typically shop fronts and retail buildings will need to have an LT of a minimum of 70% to allow for clear visibility into the space. Lower LT values of 40% can be used for residential and office buildings where the high light transmission can create glare and discomfort for the inhabitants.

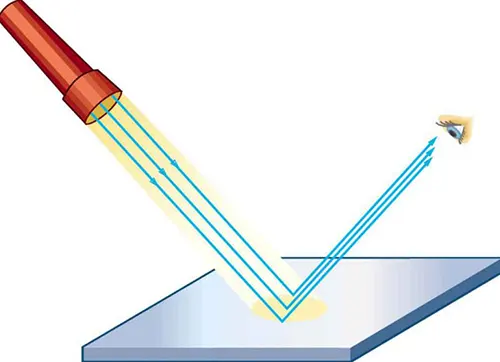

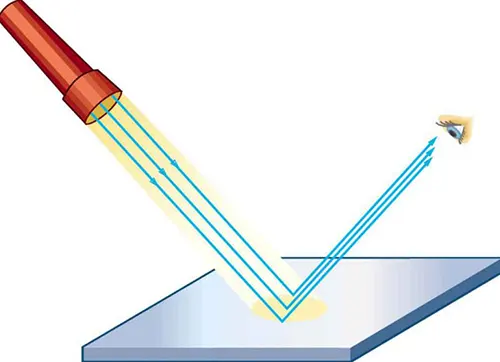

Light Reflectance (LR): When light meets a glass surface, some of the light is reflected, depending on the angle of incidence and the refractive indices of the glass, and the medium the light is coming from (e.g., air). LR is the fraction of the incident light that is reflected from the glass surface.

Light reflection is important since it is a measure of how effectively images are reflected off a glazed surface. This has a downside as well… high light reflection also means high glare. Imagine driving through the interstate highways during the summer months and all the glazed buildings along the road reflecting light onto the driver’s eyes.

This consideration is of particular importance in Middle Eastern countries where summer solar irradiation is higher than in other parts of the world. Hence light reflectance is a parameter that needs to be carefully chosen based on the location of a building. High reflective coatings are effective in reducing solar absorbance and transmittance, however, when designing for buildings lining major motorways architects and engineers need to be considerate of the safety aspect as well.

Color rendition index (CRI): (also called color rendering index), is a quantitative measure of the ability of a glazing to reproduce the color of various objects faithfully in comparison with an ideal or natural light source. It is expressed on a scale of Scale is 1 – 100. In the commercial glass, CRI indicates the effect the specific glass configuration has on the appearance of objects viewed through the glass. CRI has a direct impact on how well the users of the building see the outside environment and therefore has a direct impact on affecting the mood of the inhabitants who typically spend 90% of time indoors. Working in an office for an 8-5 job, the last thing an employee would appreciate, is to look out of the windows for a few minutes of relaxation and see grass with a strong brown/blue tinge.!!

Color rendition index (CRI): (also called color rendering index), is a quantitative measure of the ability of a glazing to reproduce the color of various objects faithfully in comparison with an ideal or natural light source. It is expressed on a scale of Scale is 1 – 100. In the commercial glass, CRI indicates the effect the specific glass configuration has on the appearance of objects viewed through the glass. CRI has a direct impact on how well the users of the building see the outside environment and therefore has a direct impact on affecting the mood of the inhabitants who typically spend 90% of time indoors. Working in an office for an 8-5 job, the last thing an employee would appreciate, is to look out of the windows for a few minutes of relaxation and see grass with a strong brown/blue tinge.!!

CRI values that are 95 and above are considered excellent, and most coated glazing provides these values, while scores below 80 are considered poor. For applications where color appearance is important or can contribute to improved aesthetics, engineers need to consider glazing with CRI above 95. Areas, where improved aesthetics could be important, include high-end hotels and retail stores, hospitals, schools, and residences. Clear glass has an inherent slightly green transmission color due to the chemical composition of its key constituent, i.e., sand.

Selectivity of Glass

An important aspect to bear in mind when designing glazed façades is the relation between the glass’s light transmission and the solar factor. Given that solar irradiation is made up of almost equal amounts of light and heat, it is never possible to enhance one characteristic without affecting the other. The selectivity of glass is expressed as the ratio between its light transmission (LT) and solar factor (SF). When the selectivity of glass is 2, it gives twice as much light versus heat. Selectivity of 0 means LT = 0 which is opaque glass.

State-of-the-art coatings have enabled the production of glazing with selectivity as high as 2.4. However, this also affects the budget of the project. It is advised to keep the selectivity to a maximum of 1.8-2.0 while specifying glazing performance for buildings. The LT and SF values must also satisfy relevant local and international codes of practice for energy efficiency and occupant comfort.

State-of-the-art coatings have enabled the production of glazing with selectivity as high as 2.4. However, this also affects the budget of the project. It is advised to keep the selectivity to a maximum of 1.8-2.0 while specifying glazing performance for buildings. The LT and SF values must also satisfy relevant local and international codes of practice for energy efficiency and occupant comfort.

Want to try digital glass printing?

Contact us to learn more about the knowledge of how to choose the glass for building. Wallkingdon Glass team of professional engineers, designers and architects is waiting to hear from you!

Wallkingdon Glass provides first-class products and services to exceed customer expectations. No matter what your project needs—from external high-rise windows to large-capacity glass in storefronts or showrooms, please contact us through the following ways: enquiry@wallkingdonglass.com

Color rendition index (CRI):

Color rendition index (CRI):